3D-printed prosthetic hand created by undergraduate students could transform access for war-torn regions

Student team develops affordable prosthetic hand addressing Ukraine's post-invasion shortage

3D-printed prosthetic hand created by undergraduate students could transform access for war-torn regions

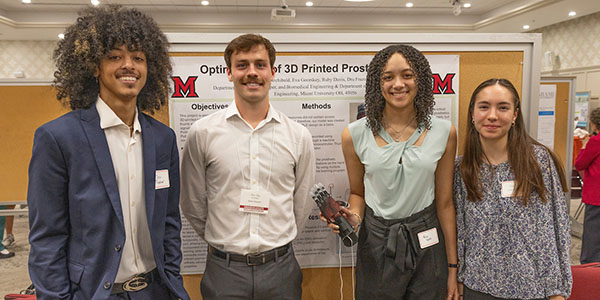

A team of four Miami University undergraduate students is working to develop an affordable 3D-printed prosthetic hand that costs less than $100 and can be produced in 36 hours, addressing a shortage of prosthetic devices in areas impacted by military conflicts.

This innovative design incorporates machine learning and non-invasive muscle control technology that the team plans to test in a human subjects study in fall 2025.

“The Optimization of 3D Printed Prosthetic Hands” research project addresses a global accessibility issue in prosthetics.

“We pursued this project because we felt there was a need that wasn’t met,” said Tim Archibald ‘25, one of the four team members. “Prosthetic hands are costly, take a long time to produce and replace, and normally involve painful procedures to implement.”

Another team member, junior Eva Goorskey, added, “There’s a lot of really advanced prosthetics out there, but they’re very expensive and we want to increase the quality of life and also preserve the functionality of a hand as much as we can.”

The team’s design uses myoelectric pathways and machine learning to control thumb movement laterally and vertically through non-invasive electromyography. Different polymer finger pads with varying stiffness levels and adhesion capabilities provide enhanced grip and self-healing properties.

Archibald and Goorskey, along with juniors Ruby Davis and Dru Frazier, were inspired to tackle the issue of prosthetics in crisis-affected areas when visiting faculty member Borys Prydalnyi gave a talk in the College of Engineering and Computing about Ukraine’s critical prosthetic shortage following Russia’s 2022 invasion.

With Chemical, Paper, and Biomedical Engineering chair and professor Jessica Sparks and Chemistry and University Distinguished Professor of Biochemistry Dominik Konkolewicz as their mentors, the team got to work.

The team reworked the Phoenix Hand V3 design from e-Nable — a web-based community that creates prosthetics for those in need — to focus on achieving full anatomical functionality. Their prototype was 3D printed at King Library’s Makerspace.

After presenting at the Undergraduate Research Forum (URF) in April, the team will continue its work with human subjects testing this fall to evaluate the prosthetic hand's functionality and user experience. The device's myoelectric signal processing and machine learning capabilities will allow it to adapt to each user's unique biological electrical impulses for accurate movement. This testing phase aims to refine the design into a final prototype that achieves both functional and humanitarian objectives.

“(Konkolewicz and I) were very proud of the students for their scientific and technical progress and also for their excellent teamwork,” Sparks said. “The project is ongoing and much remains to be done, but this team is highly motivated and it has been a pleasure to see how self-motivated and independent they are and how well they communicate and contribute to the group's success.”

All four team members reported positive impacts from the research experience. The project allowed Frazier, a Computer Engineering major, to expand his professional network. Meanwhile Davis, a Biomedical Engineering major, said she gained valuable 3D modeling experience relevant to her tissue engineering career goals.

“As a chemical engineering major, a lot of this is not something I’m going to learn in class,” Goorskey said. “Circuitry, machine learning, material science, and 3D printing and modeling: All of these things have enriched my college experience and also my skillset as a future engineer.”

Archibald, currently a manufacturing engineering intern at medical technology company Stryker, credits getting involved in Sparks’ research with preparing him for this professional role. He graduated with a bachelor’s in Biomedical Engineering and plans to return to Miami to pursue a master’s in Business Analytics.