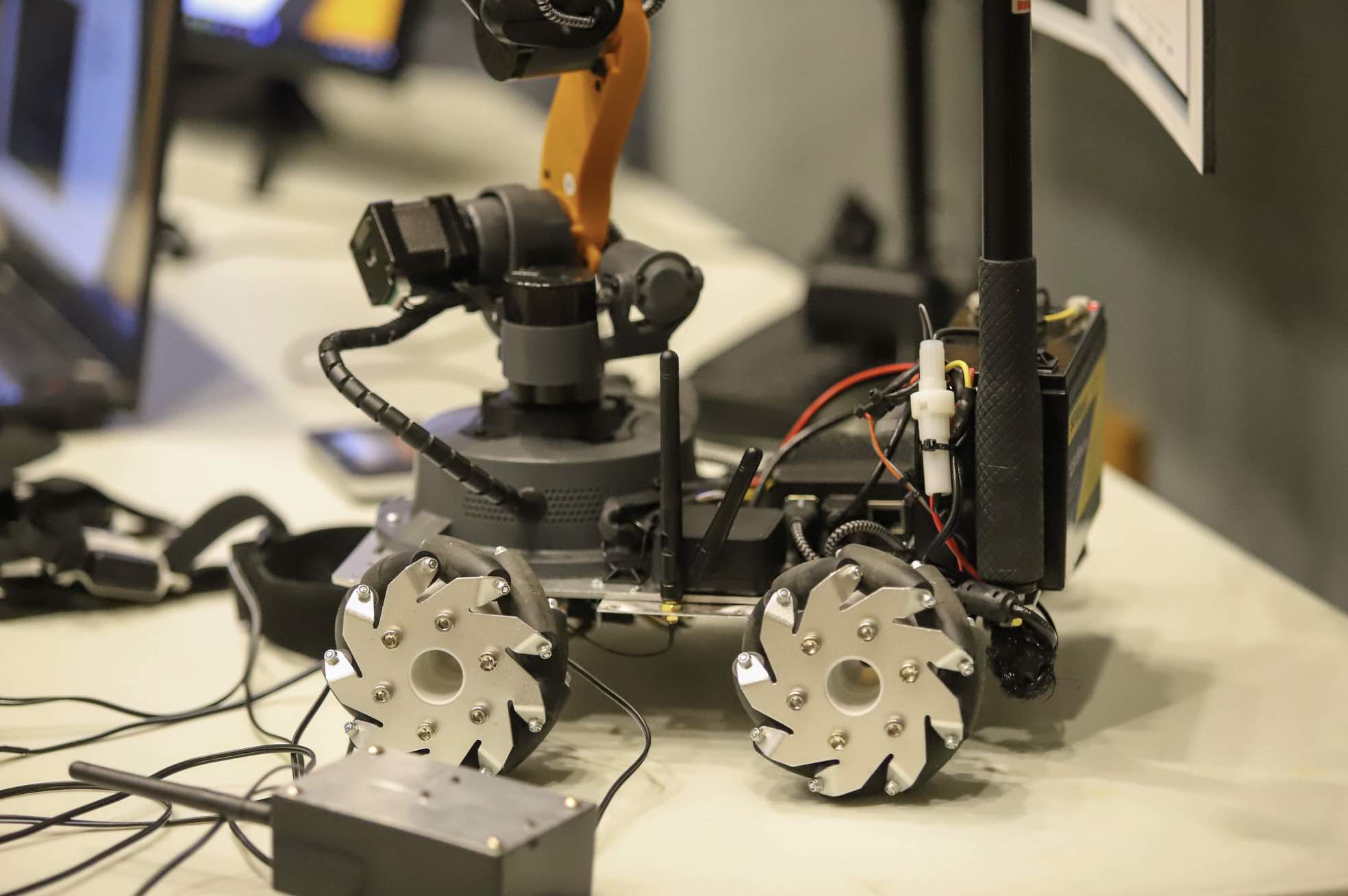

ENT Senior Design Day 2024

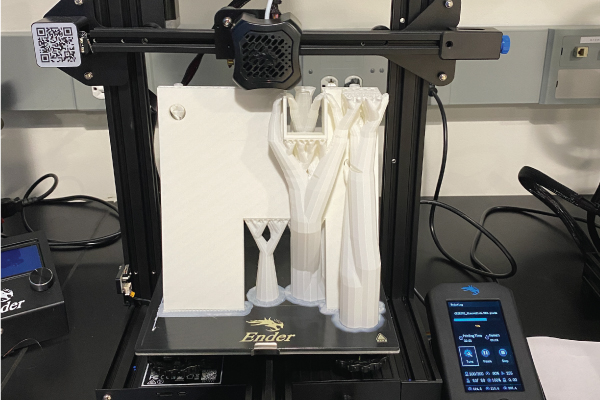

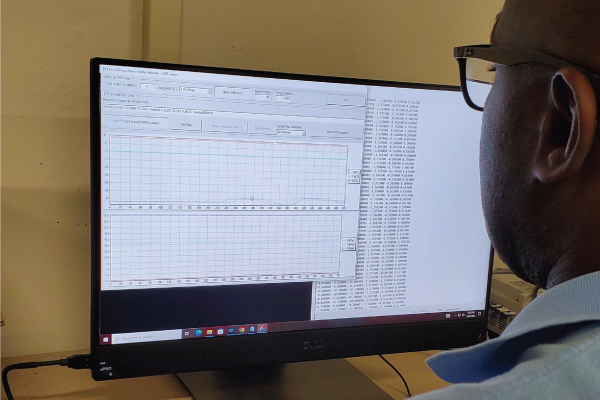

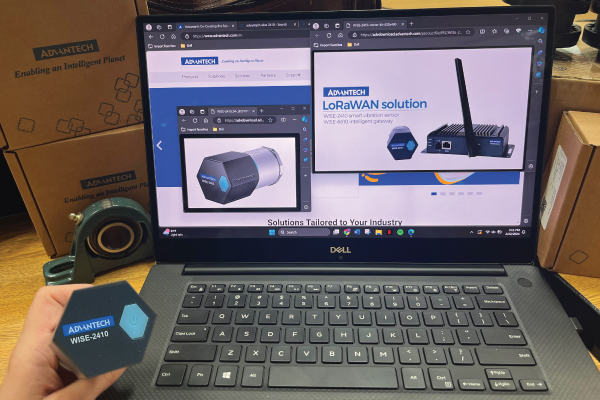

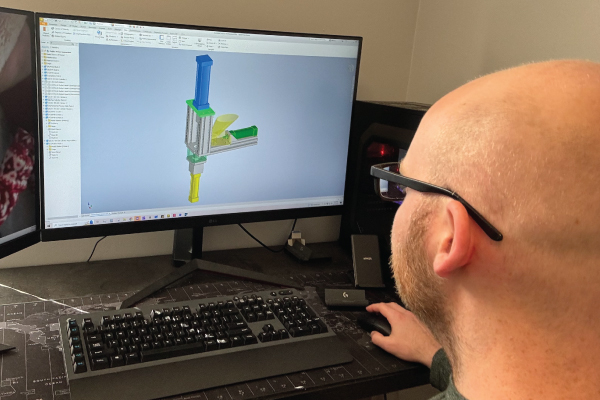

Student teams conduct major open-ended research and design projects. Elements of the design process including establishment of objectives, synthesis, analysis, and evaluation are integral parts of the capstone. Real-world constraints such as economical and societal factors, marketability, ergonomics, safety, aesthetics, and ethics are also integral parts of the capstone. ENT 497: feasibility studies performed; ENT 498: implementation, testing, and production of design.

Through the Lens

On Friday, Apr. 26 ENT seniors shared their research results and presented design projects to ENT alumni and community partners.

| ROOM A | ROOM B |

|---|---|

|

9:30 a.m

|

9:30 a.m

|

|

10 a.m.

|

10 a.m.

|

|

10:30 a.m.

|

10:30 a.m.

|

|

11 a.m.

|

11 a.m.

|

|

11:30 a.m.

|

11:30 a.m.

|

12-1:30 p.m.

|

|

|

1:30 p.m.

|

1:30 p.m.

|

|

2 p.m.

|

2 p.m.

|

|

2:30 p.m.

|

2:30 p.m.

|

|

3 p.m.

|

|

|

3:30 p.m.

|