Gaining a competitive edge through CEC's SASI workshop

Sofie Dwyer, Chemical Engineering major, shares her experience from CEC's Systems and Automation Springboard to Internship workshop.

Gaining a competitive edge through CEC's SASI workshop

The Systems and Automation Springboard to Internship (SASI) workshop is a three-week intensive program that introduces students to the fundamentals of the process control field and allows us to see real-world applications. The program consisted of lectures, hands-on activities, a plant tour and visits from industry professionals.

The Systems and Automation Springboard to Internship (SASI) workshop is a three-week intensive program that introduces students to the fundamentals of the process control field and allows us to see real-world applications. The program consisted of lectures, hands-on activities, a plant tour and visits from industry professionals.

The most important aspect of the SASI workshop is that every student in it has already found an internship for the summer. Our dedicated faculty makes sure to get our names out to companies so we can find a process control-based internship to get us additional practical exposure in the field. Sponsoring companies this year included Avery Dennison, Greif, International Paper, ND Paper, PCA, Sonoco, and WestRock.

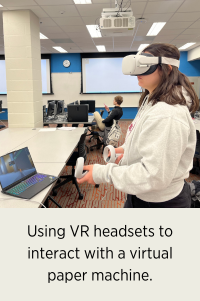

Our workshop started off with lectures on automation and control to introduce us to the relevant terminology, as well as the basis of DCS and SCADA systems. The best part of the SASI workshop was our ability to do so many hands-on activities. We were lucky enough to have Valmet come in with two such activities. The first was a digital twin of an actual plant on their DCS system. We were able to go through the pulp and paper mill on the DCS and work with cutting-edge technology used in industry. The system allowed us to see not only how to virtually change flow inputs and the impact, but it also allowed us to interact with things like interlocks that we will see once we are on-process at our internships. The second Valmet activity was our introduction to their Virtual Reality training system. We put on VR headsets and got to interact with a virtual paper machine, as well as participate in some virtual safety training that industry professionals will go through before they begin working on their machines.

Our workshop started off with lectures on automation and control to introduce us to the relevant terminology, as well as the basis of DCS and SCADA systems. The best part of the SASI workshop was our ability to do so many hands-on activities. We were lucky enough to have Valmet come in with two such activities. The first was a digital twin of an actual plant on their DCS system. We were able to go through the pulp and paper mill on the DCS and work with cutting-edge technology used in industry. The system allowed us to see not only how to virtually change flow inputs and the impact, but it also allowed us to interact with things like interlocks that we will see once we are on-process at our internships. The second Valmet activity was our introduction to their Virtual Reality training system. We put on VR headsets and got to interact with a virtual paper machine, as well as participate in some virtual safety training that industry professionals will go through before they begin working on their machines.

The lectures we had each week were met with real-world applications side by side. We were able to work with both Python coding and an Arduino. We learned about first order plus dead time (FOPDT) models and we were able to build our own in Excel and Python. The functional use of Excel especially stood out to me, as I have used Excel extensively in my previous internship. I know I will bring that practical knowledge with me to my internship this summer, and my participation in the SASI workshop will help me stand out.

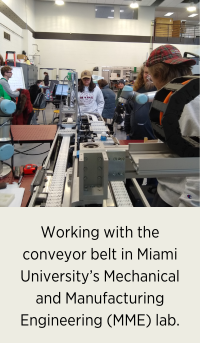

Another great lab we were able to do was coding a conveyor belt in the MME lab. This is a lab that is normally done in a 400-level MME class, but our participation in the SASI workshop allowed us to experiment with ladder logic early on. The lab required us to use ladder logic to control four stoppers and their corresponding sensors to detect when a plate passing through had a load on top. If the load was present, the stoppers stopped the load so it could be removed. We also coded a Human Machine Interface (HMI) to allow us to control the speed of the conveyor and the release once the load has been removed. This was a time-consuming lab; however its ability to draw direct connections to a vast number of fields made it an incredibly worthwhile one.

Another great lab we were able to do was coding a conveyor belt in the MME lab. This is a lab that is normally done in a 400-level MME class, but our participation in the SASI workshop allowed us to experiment with ladder logic early on. The lab required us to use ladder logic to control four stoppers and their corresponding sensors to detect when a plate passing through had a load on top. If the load was present, the stoppers stopped the load so it could be removed. We also coded a Human Machine Interface (HMI) to allow us to control the speed of the conveyor and the release once the load has been removed. This was a time-consuming lab; however its ability to draw direct connections to a vast number of fields made it an incredibly worthwhile one.

On the second to last day of the SASI program, we were brought on a tour of a nearby paper mill. We got to see the paper machines they had, as well as their process control centers in the plant. It allowed us to see firsthand the real-world applications of our learnings.

On the second to last day of the SASI program, we were brought on a tour of a nearby paper mill. We got to see the paper machines they had, as well as their process control centers in the plant. It allowed us to see firsthand the real-world applications of our learnings.

Participating in the SASI workshop was definitively one of the best decisions I have made in my college career. It allowed me to learn these incredibly important skills that I will use in industry without the distractions of other classes. The skills we learned have already started to be used in my current classes, and the networking opportunities that SASI gave us were priceless. I would recommend anyone considering the SASI workshop to put their resume in the bucket next fall, as process control engineers are in high demand, and the workshop can only give you a competitive edge.