Building future engineers: The impact of MARI

12 students participated in the J-term Maintenance and Reliability Internship (MARI) workshop, where they gained hands-on experience and learned from guest speakers as they prepared for their summer internship.

Building future engineers: The impact of MARI

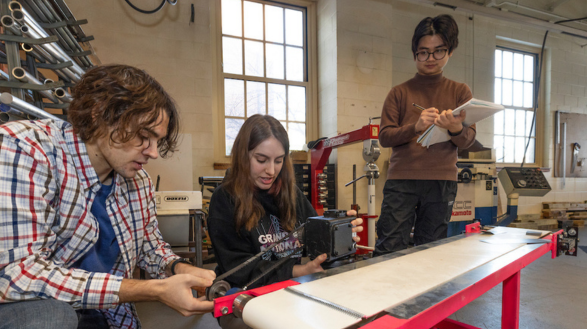

The College of Engineering and Computing (CEC) has had another successful year hosting the Maintenance and Reliability Internship workshop (MARI). Twelve students were selected to be sponsored by a company to attend, and were able to spend the three weeks learning about proper ways to maintain machinery through guest lectures and hands-on practice. At the end of the program, they tested their knowledge by building a conveyor belt and developing a maintenance plan. Rachael Harff and Eddie Thant, both sophomore Mechanical Engineering majors, spent their J-term building skills that will prepare them for their summer internships.

MARI gives students a chance to gain additional knowledge that they may not have been exposed to before. “I think the most surprising thing for me personally was how much there is for me to learn and how things are really different in a more industrial sense. Particularly in our first week, we had a lot of people from industry, which means that they bring a different view to the table versus the professors here at Miami. It's really interesting to see how things are done, like nomenclature and how it is used differently in industry,” says Thant.

Students also get the opportunity to learn about what their lives will be like once they transition into the industry. “MARI has helped me understand a lot more about what engineers do,” Harff said. “This is helping me visualize my future career because of the chance to hear about an engineer's day-to-day experience.” Through this workshop, Harff was able to learn more about what to expect at her internship.

MARI has a variety of hands-on learning experiences for students to participate in, including performing maintenance on machines, learning how to weld, and working as a team to design a conveyor belt. Throughout these activities, challenges arose that students learned to work through. “We learned how to work as a team while working on the conveyor belt. Many people have different ideas, and they clash with other people's ideas, which can take up a lot of time.”

Harff and Thant will both be working for WestRock—a paper and packaging company—this summer. After learning about the technical side of his internship, Thant focused on developing soft skills during MARI. “The thing I’m most looking forward to learning is not anything like a hard technical skill, but more of the soft skill of engaging with what I am learning. I want to make sure I develop the skill of learning and being very enthusiastic about it, even when you don't understand it at first. I think that will be the most important skill going into my internship.”

Learn more about the MARI workshop here.