Paper planes and automobiles: Toyota shows students better methods of making

How does making a paper airplane make someone a better manufacturing and supply chain expert?

Paper planes and automobiles: Toyota shows students better methods of making

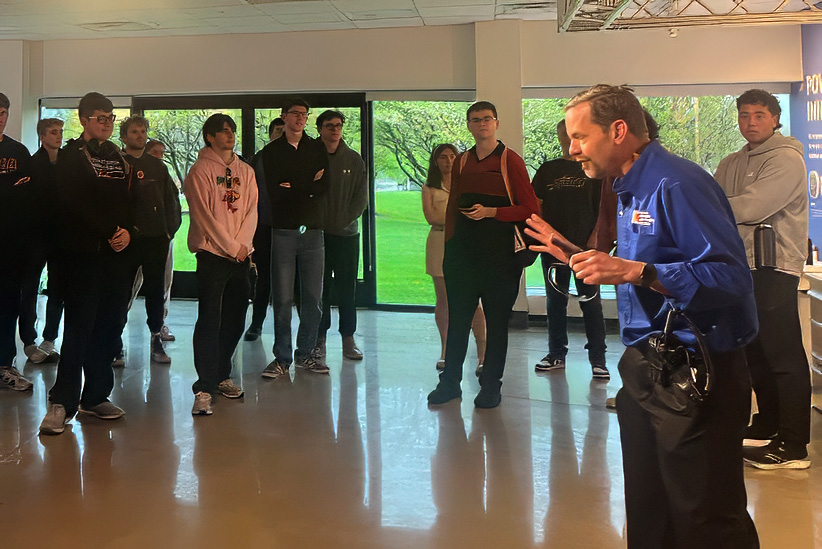

For several years, Farmer School of Business management professor John Ni has been taking supply chain operations and management students on a field trip to Kentucky to visit one of the leaders in lean manufacturing — the Toyota auto plant in Georgetown.

“They tend to think a lot of jobs are in the warehouse, logistics, transportation. For me as an operations management person, I'm more interested in trying to expand student understanding that supply chain management is not only about the logistics and the warehouse business, but has a lot more to do with manufacturing,” he said.

Lean manufacturing is a method aimed primarily at eliminating waste and maximizing efficiency in manufacturing processes to deliver higher quality products at lower costs. The method is based in large part on the Toyota Production System that the company implemented in the 1950s and 1960s.

“When you see the manufacturing of a car, which involves over 20,000 components, and you see the complexity, the amount of coordination, the amount of seamless planning, and then execution that you need to make a vehicle, that really opens students’ eyes to operations management and the complex beauty of manufacturing itself,” Ni said.

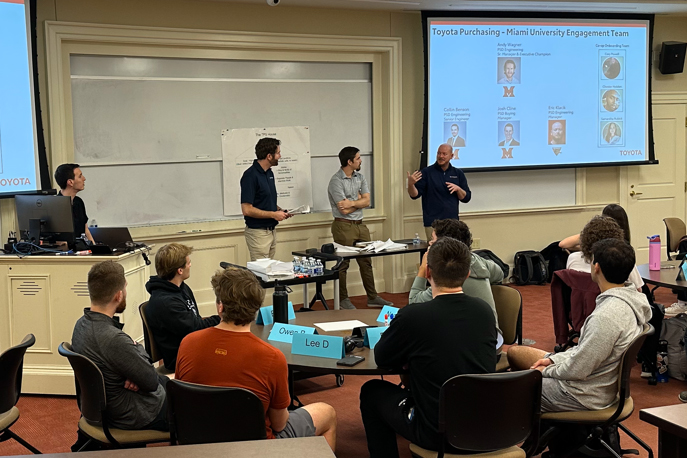

This semester, only days after that visit, a quartet of Toyota executives came to Ni’s class at the Farmer School to continue that learning process.

“We introduced concepts of the Toyota Production System from a training class we call Airplane Factory Simulation. This class is a foundational class within our Toyota North American Purchasing Department,” Andy Wagner, Senior Manager at Toyota North America and 2003 Miami University alum, said. “It offers a mix of presentation and interactive activities applying the concepts in real time ultimately stressing the importance of both quality and process design in order to meet customer needs.”

The training class is normally four hours long, but Wagner and his team created an 80-minute version to fit the class period.

“The task seems very simple; making a paper airplane. But it's not,” Ni said. “They have several different airplanes models with different folds, different color, different clips, all from a standard sheet of paper. So that adds some complexity in what seems to be a simple sort of assembly line. Students have to figure out, ‘How do I do this quicker? And still satisfy the customer?’”

“I was very impressed with the students’ knowledge of Toyota, and more so their enthusiasm to learn TPS. Putting myself in their shoes when I was at Miami years ago, they were light years ahead of where I would have been,” Wagner said. “The students were professional, knowledgeable, and eager to learn. It was a very nice change of pace to step away from the day-to-day job.”

“The visit to Toyota is for them to see the operation with their own eyes. And then the visitors from Toyota gives them a chance to look at a little bit higher level, so that we can see the framework and the structure behind all these practices,” Ni said.

Ni said that he hopes the experience will help place more graduates at Toyota, but notes that the experience could be helpful in many careers.

“The Toyota Production System is not only for automotive industries. They’re also helping a lot of other industries to do it, like furniture manufacturers, hospitals, etc.” he said. “I think that there's a lot of utility for students who can master or understand the lean practice and the production system that will really help them more in their future careers.”

“Their enthusiasm fortunately was a great reminder to me why I enjoy my job and the company I work for,” Wagner said. “It’s exciting what Miami has to offer within this program and we are looking forward to tapping into this talent to bring to Toyota in the future.”