The promise of autonomous, real-time factory virtualization brings national funding to Miami

Clayton Cooper, Ph.D. receives an NSF grant to advance manufacturing operations through digital twinning

The promise of autonomous, real-time factory virtualization brings national funding to Miami

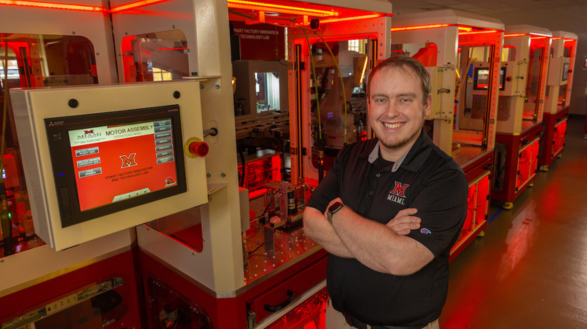

Miami University is home to a grant recipient from the National Science Foundation (NSF) and a rising star in the field of manufacturing processes. Clayton Cooper, Ph.D., assistant professor in the Department of Mechanical and Manufacturing Engineering, has secured funding of just over $199,000 from NSF through its Engineering Research Initiation (ERI) program. It’s a significant achievement for a researcher early in his career. His project – Autonomous Digital Twinning of Manufacturing Systems Through Deep-Learning-Enabled Computer Vision and Unmanned Aerial Vehicles – could transform the way factories operate.

ERI grants are highly competitive, rigorously determined, and must fulfill their mandate to advance the careers of innovative researchers and broaden participation in science and engineering. Cooper’s proposal offered a winning mix of technical innovation, real-world applicability, and student opportunity.

Digital twinning is the virtual recreation of physical objects and surroundings – a “digital twin.” The practice began with NASA in their effort to understand the reasons behind the oxygen-tank explosion afflicting Apollo 13. Subsequently, they incorporated it into the design process of every space mission. Today, digital twinning is used by many manufacturers to anticipate equipment failure and improve production efficiency and safety.

Cooper aims to advance digital twinning, creating a system that runs autonomously through self-directed drones. “We’re solving a problem many people view as impossible to solve,” Cooper said. “Who would think you could track all of your shop assets in real time? But I showed the reviewers that it's possible and that I have the know-how to make it happen.” He also credits his demonstrated commitment to training and supporting the next generation of researchers, specifying in his application funding for three graduate-student researchers, as well as significant undergraduate participation.

Over the next two years, Cooper and his rotating team of nine student researchers will put NSF funds to work creating a system that provides continuous, real-time data on the exact movements across a factory floor and initiates anticipatory adjustments, all on its own. The project’s first year is devoted to developing software to analyze and manage incoming data. The second year involves creating specialized, AI-enhanced cameras to collect data on production dynamics and attaching them to drones which will fly themselves and auto rotate to recharging stations.

The project’s ultimate goal is creating a better way to monitor and manage factory operations. Potential benefits feature optimized efficiency and productivity. For Cooper, advantages of particular interest are raising worker safety and reducing their physical toil. “My parents worked at GM Lordstown,” he said. “I saw how lack of technology destroyed their bodies over time. It inspired me to pursue mechanical engineering.” He summarizes his inspiration and research focus succinctly, “I want to make human lives easier.” With a national funding award under his belt, he’s off to an enviable start.